What Makes a Construction Product Sustainable?

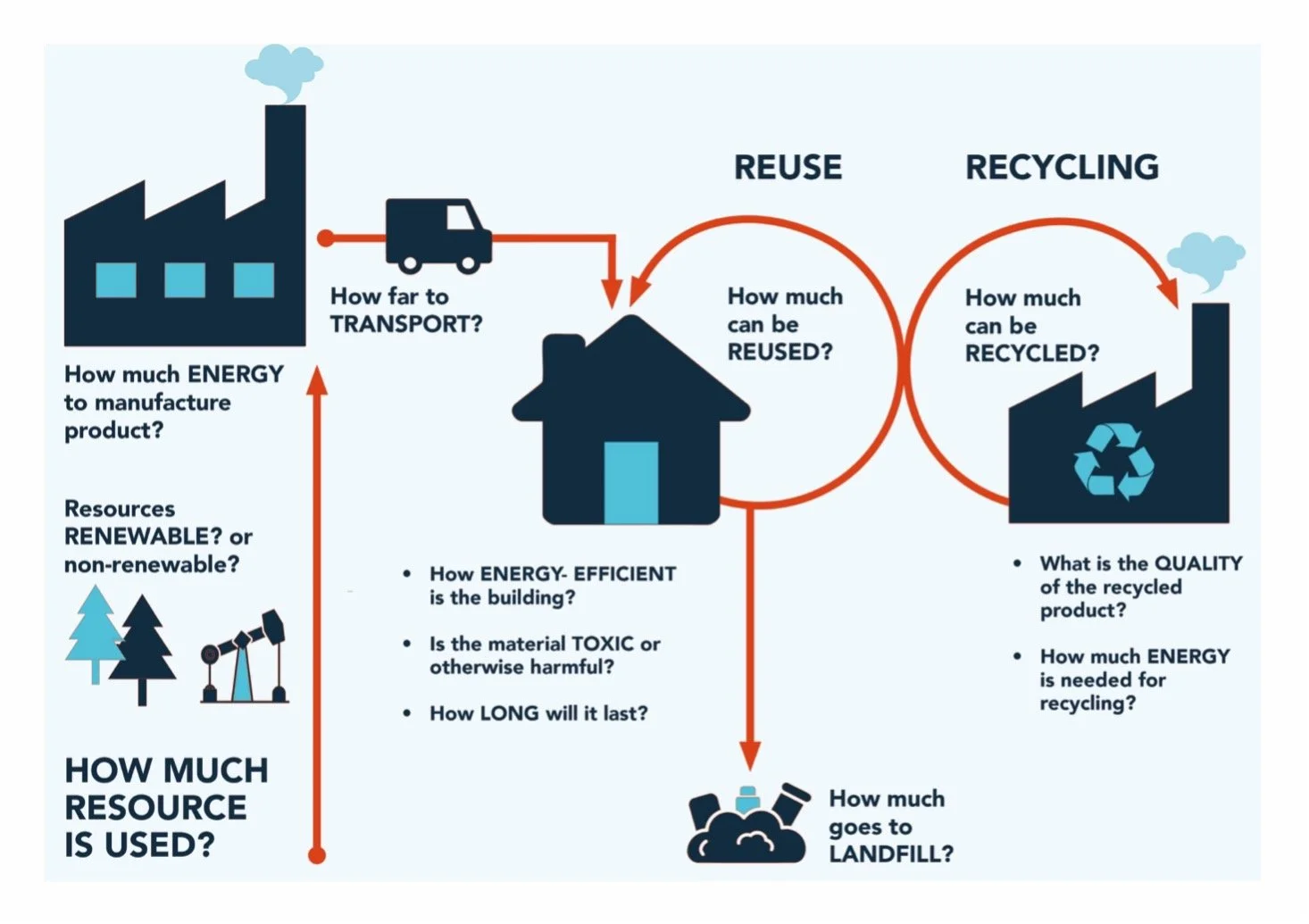

Building more sustainably involves considering more than just immediate performance of a product by assessing environmental impacts across its entire life cycle. This article discusses some of the key factors that affect the sustainability of construction products, which can be considered when you are selecting materials. This includes considering what the product is made of, how long it lasts, where it was made, and the options for reuse or recycling at end-of-life (Figure 1).

Figure 1: Key factors influencing the sustainability of building products

1. Energy and Resource Inputs and Outputs

Energy, carbon, and/or toxicity of all the inputs and outputs of a product should be considered over its lifetime, from extracting the raw materials to manufacturing, processing, transportation, and installation on site.

Energy - Some materials are very energy-intensive to produce, such as concrete and steel. To make this worse, this energy may come from non-renewable sources such as fossil fuels (coal, gas etc.), rather than renewable energy sources (e.g. hydrothermal). Other materials may require less energy to create and can be harvested directly from the environment, such as timber and soil.

Inputs – It is important to consider ALL of the materials that are used to make a building product. Some of the materials may make the product difficult to reuse or recycle or may be harmful to the environment and/or people. For example, a plastic-based construction product would likely include chemical additives (e.g. plasticisers) but may also contain non-plastic components which prevent recycling at end of life.

Outputs - The outputs from the extraction, manufacture and distribution of the building product should also be considered, for example, any byproducts, heat energy, waste, and wastewater. These outputs may need to be treated before disposal but then again, excess energy may be reused in the process and so require an overall smaller energy input. So, you can see that outputs can be useful as well as problematic!

From a sustainability standpoint, production that requires little energy, few inputs and generates little waste is the most preferred.

2. Durability and Longevity

It is important that products are selected appropriately and in accordance with how long they need to last. A structure intended to last for decades made out of a durable material, even if it took more energy to produce (called higher “embodied energy”), may have a lower environmental impact in the long-term as it needs less maintenance and lasts for longer. By contrast, a product which has only been designed to last for a few three years but is used for decades, may require frequent maintenance and replacement, which would increase its environmental impact overall. Buildings that can be reused and repurposed for centuries to come can have very low energy and resource inputs per year used compared to buildings that are frequently rebuilt.

3. Manufacturing and Transport Impacts

Where a product is made also has a bearing on its environmental footprint. Using locally made products is usually preferable to imported products, as transport emissions will be much lower. Local products may also require less packaging than imported materials and so generate less packaging waste.

Producing materials in New Zealand is preferable, thanks to our low-carbon electricity grid—around 80–85% of our electricity comes from renewable sources. While about 70% of our overall energy use still relies on fossil fuels, local production allows for better oversight of manufacturing processes. It is easier to ensure environmental standards are met, especially when it comes to managing waste and toxic byproducts. By keeping production close to home, we reduce the risk of these impacts occurring in regions with weaker environmental regulations.

4. End-of-Life Considerations

What happens when the product is no longer useful? When selecting a building product, think about the options available, for example::

Can it be easily reused? Can it be recycled locally? Is it biodegradable? Are there options available other than landfill? Can it be deconstructed quickly and easily?

Ideally, products that can be reused and recycled are prioritised because they are less likely to end up in landfill (often called “more circular”)

And don’t forget to consider products that contain hazardous substances (for example, products containing heavy metals) that can make disposal and management at end-of-life difficult. They may require specialised processing, which increases environmental and financial costs.

5. Reusability and Recyclability

Products which can be easily reused or recycled generally have a lower environmental impact. The reuse and recycling of products reduces the need for raw materials and new products to be created (which takes both energy and resources).

Reusable products are the most ideal, as they do not require further processing or energy to be used. Ideally, these products can be easily disassembled from a building at its end-of-life, ready for reuse, and are not permanently fixed to the building (e.g. by using adhesives). For example, steel beams and timber elements.

Recycling comes after reuse in terms of environmental impact, requiring energy and sometimes material input. However, it can often reduce the need for raw material extraction in comparison to new products, which improves a product’s ‘Environmental Footprint ‘(which is how environmental impact can be measured).

It is important that the output recycled materials are of high enough quality to justify their recycling. A low-quality product that has limited market uses may offer limited environmental benefits when weighed against processing costs (and energy). For example, white or clear recycled plastic pellets have a higher market value than mixed coloured pellets, as they are easier to reprocess and customise during manufacturing.

Recycling high-quality, single-stream materials back into the same product (e.g. shrink wrap back into more shrink wrap) is the most preferred pathway. This increases the chances that it can be recycled repeatedly with minimal virgin material inputs.

‘Downcycling’ occurs when a lower-quality product is formed and often occurs when multiple material waste streams are used to create a product. They are usually very difficult to separate back into individual materials and therefore limit opportunities at the end of the products life (e.g. park benches made of mixed plastics).

It is also important to consider logistics, for example, recycling only has environmental benefits if the process is practical and recycling is actually achievable If recyclers are located far from the source, the cost of transportation may make recycling unlikely and the energy used (and associated emissions) from transporting the materials may outweigh the gains from recycling.

Conclusion

Sustainability is not one-size-fits-all—what works well in one region might not be the most sustainable option in another. Factors like how electricity is generated, the availability of local recyclers and transport options, and the intended use of the material all play a role in a product’s environmental footprint.